PDF(2201 KB)

PDF(2201 KB)

Virtual Equipment Maintenance Disassembly Sequence Planning with the Application of Jack

YE Lin, SHEN Yan-an

PDF(2201 KB)

PDF(2201 KB)

Virtual Equipment Maintenance Disassembly Sequence Planning with the Application of Jack

Virtual disassembly as the burgeoning means of maintenance technology, existing deficiencies in maintenance disassembly process planning. To handle this problem, this paper introduces interpretative structural model on the basis of Petri-net, and constructs Virtual Disassembly Interpretative Structural Model Petri-net, which is constructed to realize the subsystem division and hierarchical division of complex equipment components. Taking the ergonomic factors as the basic constraints of the disassembly process, this paper realizes the definition, evaluation and secondary development for the ergonomics indexes with the platform of Jack, which improved the description of maintenance disassembly process; combined with genetic algorithm,efficiently it achieves the virtual maintenance disassembly sequence intelligently planning for a certain type of gearbox.

Interpretative Structural Model; Petri-net; ergonomics; virtual maintenance; sequence planning {{custom_keyword}};

表1 VDISMPN的要素组成 |

| 要素 |  |  |  | W(pi,tj)弧权值 |

|---|---|---|---|---|

| 约束 关系 |  |  |

表2 维修活动可达范围评价 |

| 关节 | 有效范围 | 舒适范围 |

|---|---|---|

| 肩关节(θ4) | -45°~+180° | +15°~+35° |

| 肩关节(θ5) | -40°~+140° | +40°~+90° |

| 肘关节(θ7) | 0°~+145° | +10°~+85° |

表3 维修活动可视范围评价 |

| 参数名称 | 有效范围 | 舒适范围 |

|---|---|---|

| 视距/mm | +120~+1500 | 250~+500 |

| 水平视角/° | ±0~35 | ±3~15 |

| 垂直视角/° | ±0~35 | ±3~25 |

表4 基因编码形式 |

| x1 | 1 | 2 | … | L |

|---|---|---|---|---|

| x2 | - | R1 | … | RL-1 |

| x3 | - | Z1 | … | ZL-1 |

表5 VDISMPN模型变迁及层级 |

| 层级 | 变迁 | 含义 |

|---|---|---|

| Ⅰ | T00~T06 | 空变迁 |

| T25 | 拔出变速齿轮 | |

| Ⅱ | T4,T20,T23 | 摘取轴承 |

| Ⅲ | T3,T7,T21 | 取下密 封垫圈 |

| T2,T5,T22 | 拆卸限位环 | |

| T1,T6 | 拆卸传动杆 | |

| Ⅳ | T24 | 取下顶盖 |

| Ⅴ | T8,T9,T10,T11 | 拆卸六角头螺母 |

| T12,T13 | 拆卸沉头螺母 | |

| T14 ~T19 | 拆卸弹性垫圈 |

| [1] |

郝建平. 虚拟维修仿真理论与技术[M]. 北京: 国防工业出版社, 2008.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [2] |

刘德明. 武器装备虚拟维修演示训练系统研究[D]. 西安: 西安工业大学, 2014.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [3] |

张王卫, 苏群星, 刘鹏远. 虚拟维修拆卸序列智能规划研究[J]. 系统仿真学报, 2013, 25(8):1912-1918.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [4] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [5] |

王占海, 翟庆刚, 虞健飞, 等. 考虑工效学的飞机维修性虚拟分析与验证[J]. 中国民航大学学报, 2009, 27(4):56-59.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [6] |

戴永峰. 民用飞机维修性虚拟分析与验证方法研究[D]. 南京: 南京航空航天大学, 2005.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [7] |

孙有朝, 邓华伟. 虚拟环境下民用飞机维修性评估与验证技术[J]. 交通运输工程学报, 2006, 6(1):93-97,112.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [8] |

吴哲辉. Petri导论[M]. 北京: 机械工业出版社, 2006.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [9] |

李彬, 崔汉国, 李正民, 等. 基于共享子网合成Petri网的协同虚拟维修系统[J]. 中国修船, 2015, 28(5):45-49.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [10] |

张雷, 刘志峰, 杨明, 等. 基于解释结构模型的产品零部件拆卸序列规划[J]. 计算机辅助设计与图形学学报, 2011, 23(4):667-675.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [11] |

陈鹏, 王春慧, 周前祥. 基于Jack的穿舱外服航天员工作空间研究[J]. 计算机仿真, 2007, 24(2):37-40.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [12] |

谭跃进. 系统工程原理[M]. 北京: 科学出版社, 2010:20-25.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

PDF(2201 KB)

PDF(2201 KB)

表1 VDISMPN的要素组成

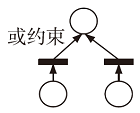

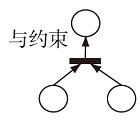

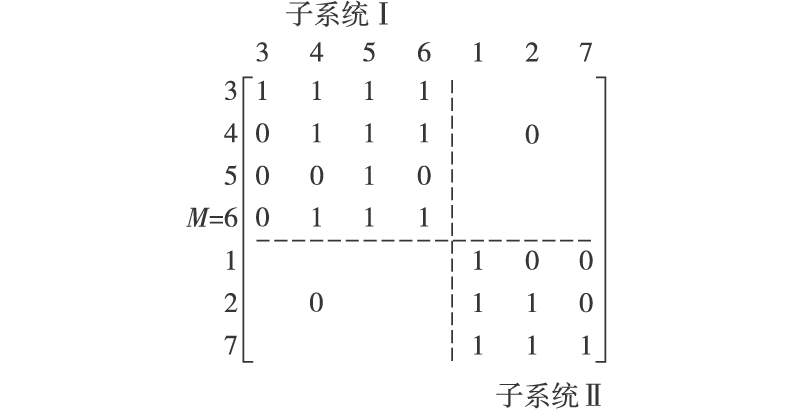

表1 VDISMPN的要素组成 图1 ISM有向图模型

图1 ISM有向图模型 图2 人体手臂关节模型

图2 人体手臂关节模型 表2 维修活动可达范围评价

表2 维修活动可达范围评价 图3 人体可视范围模型

图3 人体可视范围模型 表3 维修活动可视范围评价

表3 维修活动可视范围评价 表4 基因编码形式

表4 基因编码形式 图4 VDISMPN样本基因的解码过程

图4 VDISMPN样本基因的解码过程 图5 虚拟维修样机实体图

图5 虚拟维修样机实体图 图6 虚拟维修样机拆卸图

图6 虚拟维修样机拆卸图 图7 VDISMPN模型

图7 VDISMPN模型 表5 VDISMPN模型变迁及层级

表5 VDISMPN模型变迁及层级 图8 VDISMPN模型进化过程

图8 VDISMPN模型进化过程/

| 〈 |

|

〉 |